Paddle dryers

General

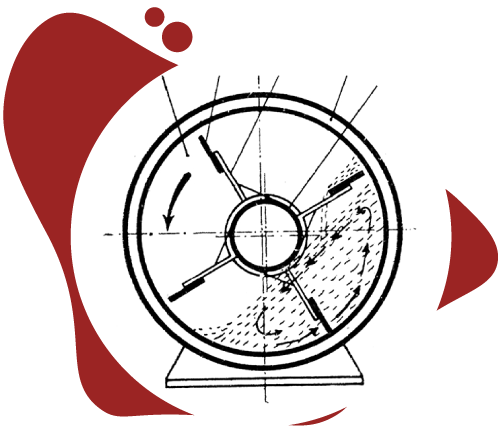

The paddle dryer consists of a horizontal, cylindrical heating jacket, a paddle mechanism which can be heated and which ensures the constant mixing of the product. For the mixing of the product to by dried, the angle of repose (inner friction angle) of the product and its change during the drying process, plays a certain role. Because, the larger the angle of repose, the higher the product is lifted from the paddle mechanism. The relevant drop height also creates a specific reduction effect in the product, which in turn has a positive effect on the drying. By adapting the paddle shape and width, the relevant product, with all its properties, can be accommodated

Operating principle

For the actual drying process, the product must come into contact with as much of the heating surface as possible. Therefore, the shape and size of the paddles, according to the drying task, must be selected in such a way that the product falls on to the heated paddle shaft, mixes continuously and evenly and spreads optimally in the dryer. Furthermore the paddles are suited to discharge the dried product from the dryer. Any potential paddle abrasion is actively prevented and does not occur.

Application

- Drying of slurries of all kinds, liquid manure, fermentation residues etc.

- Disinfection / cleaning / washing of solids (bank notes, waste etc.)

- Decontamination of soils

Advantages

- Fully-automated processes

- Operation from normal pressure to high vacuum

- Drying is possible both continuously or by batch

- Large maintenance and cleaning openings

- Fully-automated CIP (Cleaning in Place) / SIP (Sterilization in Place), possible

- ATEX, GMP and FDA compliant

- Low electric power requirements thanks to energy recovery

Disadvantages

- Mechanical impact on the product

- Increased cleaning effort, as large part of surface comes into contact with the product

- Due to the design, product residues remain in the machine