Vakuumdrehtrommeltrockner

General

Rotary drums are mainly used to dry coarse-grained, free-flowing products with a particularly low angle of repose. This application is mainly used for products where the structure should not be damaged by e.g. abrasion or pressure.

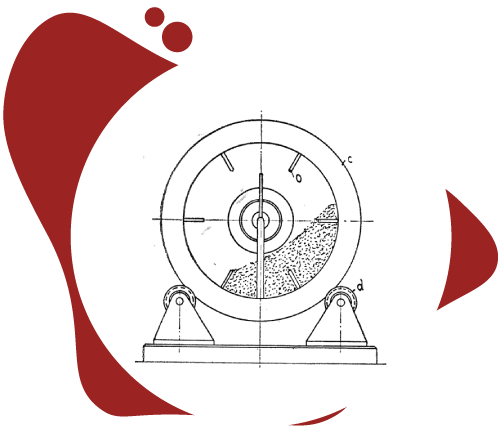

Operating principle

The rotary drum is a drum mounted in pins, with a heated jacket. With the help of additional, installed heating pipes, the sprinkled heating surface can be increased highly effectively by means of rotary movement. Screw-shaped blades are often arranged on the heating jacket, which mix the product during drying in one rotation direction.

Application

Drying of highly advanced and mechanically sensitive products such as for example cocoa beans, legumes, fruit, cereals, malt and chipping goods

Advantages

- Fully-automated processes

- Operation from normal pressure to high vacuum

- Drying is possible both continuously or by batch

- Structure-preserving and gentle product treatment due to no mechanical impact

- Large maintenance and cleaning openings

- Fully-automated CIP (Cleaning in Place) / SIP (Sterilization in Place), possible

- ATEX, GMP and FDA compliant

- Low electric power requirements thanks to energy recovery