Nutsche Dryers / Agitated Pressure Filters

General

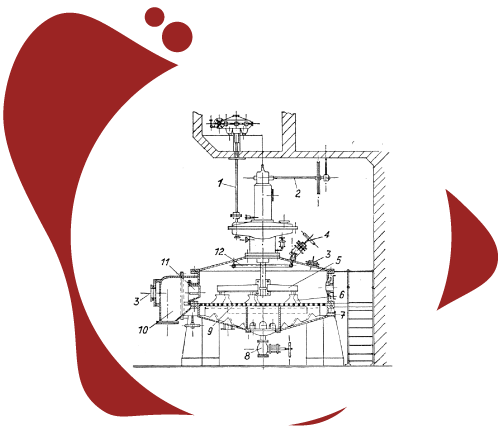

The agitated pressure filter consists of a cylinder, cover with height adjustable agitator and a filter base. The filter base can be separated from the agitated pressure filter for cleaning and maintenance purposes. The agitator is height adjustable and is used for mixing, washing, dividing, smoothing and discharging the solids. To aid reactions, the jacket and filter base can be heated

Operating principle

As the name says, the introduced product is processed by means of pressure, preferably nitrogen, under constant stirring, smoothing. The resulting filter cake is then pressed against a filter sieve and drained. The agitator takes care of 2 functions.

- Distribution of the solid substance and simultaneous smoothing of the "filter cake" (closing of any occurring cracks in the surface), in order to ensure optimal pressure distribution.

- Mixing / washing of the solid substance, with repeated adding of liquid.

Often, multiple cycles of washing and pressing follow each other.

Application

- For intensive cake washing

- Extraction of active ingredients

- Filtering, washing, resuspension

- Solids separation

Advantages

- Fully-automated processes

- Very gently on the product, as there are almost no mechanical impacts.

- Combination of multiple work steps/machines washing, extraction and drying

- Fully-automated CIP (Cleaning in Place) / SIP (Sterilization in Place), possible

- ATEX, GMP and FDA compliant

- Compact design

Disadvantages

- Relatively high residual moisture (depends on product)

- Only batch operation possible

- Small heating surface